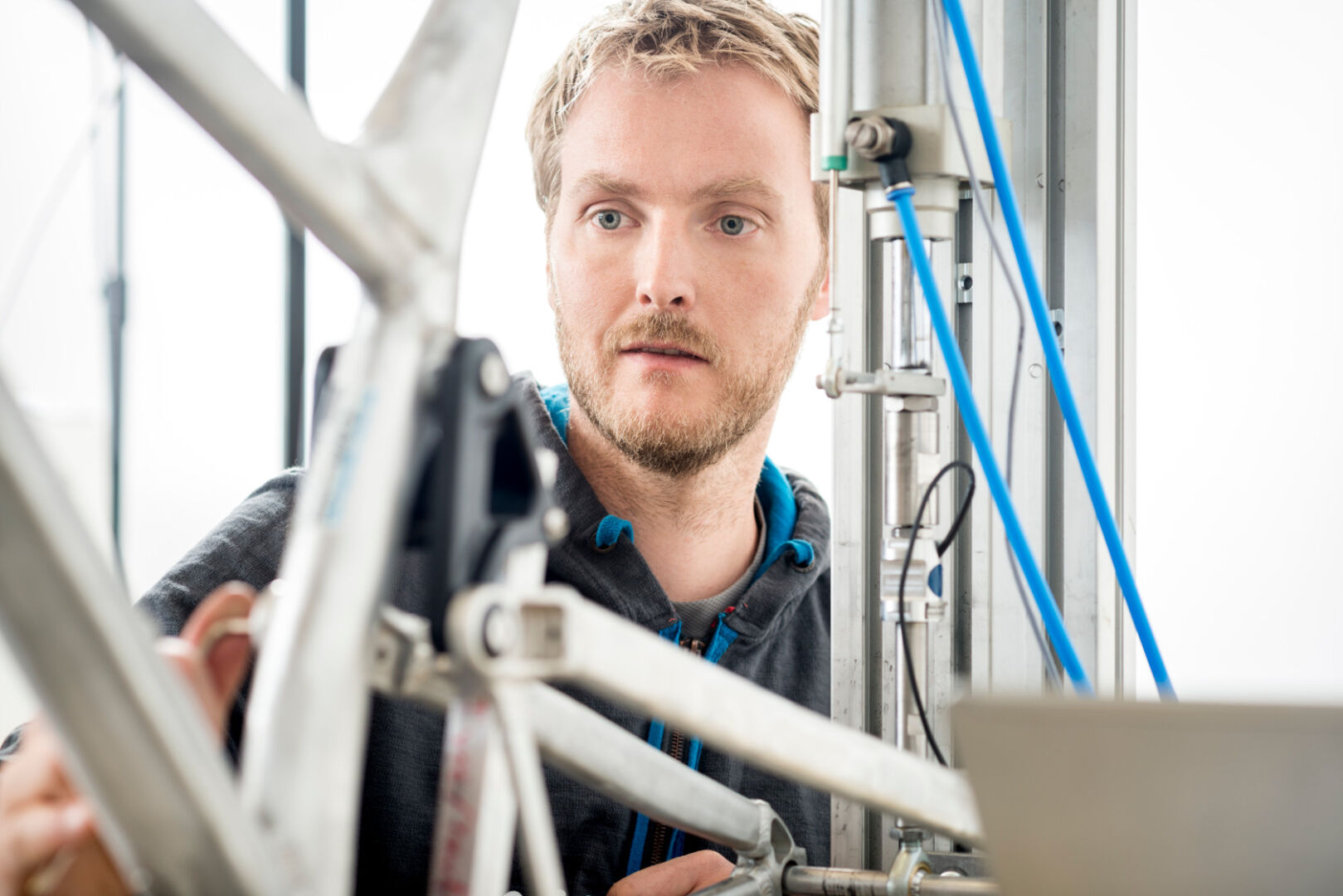

AT FIRST, THE IDEA GETS ON THE PAPER

Before our bikes come into production, it is a long way. After we had brought the first idea on paper (or on Computer), we will test several prototypes till we get to the finished production model. Those prototypes will be tested extremely till we are 100% satisfied. After this long procedure, we give the OK for the production run.